產品

特色

• 靜音 -採用防振動,低噪音的行星設計構造。低於65dB。

• 高精度低背隙 -最高5弧分可選擇

• 高效率- 一段效率高達96%和二段93%。

• 高扭矩與穩定性

|

Model Number |

DF Series High Precision Planetary Gearbox |

|

Speed Reduction Method |

Planetary gear mechanism with designed tooth profile |

|

Efficiency |

95% per stage gearbox |

|

Shock Load |

300% as there are only compressive forces rather than shear forces on the tooth |

|

Gear box Mounting |

Flange Mounting, Foot mounting parts sold separately |

|

Reduction Ratio |

Up to 1:10 per stage 1:1000 on 3-stages |

|

Capacity Range |

100Watt to 11,000Watt |

|

Enclosure |

Totally enclosed IP55 |

|

Power Source |

Servo motor, stepper motor |

|

Backlash |

Single Stage: below 5arcmin Double Stages: Below 8arcmin |

|

Reduction Gearbox Lubrication Method |

High viscosity anti-separation grease |

|

Method of Coupling with Driven Machine |

Coupling, gears, chain sprocket or belt |

|

Standard |

CE, UL, CSA, ISO 9001, ISO14001 |

|

Warranty |

1 Year Limited Warranty |

產品

規格

|

Specification 規格 |

Ratio減速比 (Stage 段數) |

DF060 |

DF090 |

DF120 |

DF150 |

|

|

Instantaneous Max. Output Torque 瞬間最大輸出扭矩 T2B (Nm) |

3/9/10/30/100 |

132 |

504 |

780 |

1428 |

|

|

4/12/16/20/28/40 |

162 |

564 |

918 |

1680 |

||

|

5/15/25/35/50 |

138 |

528 |

855 |

1560 |

||

|

7/21/49/70 |

144 |

540 |

879 |

1608 |

||

|

Defined Output Torque 額定輸出扭矩 T2N (Nm) |

3/9/10/21/30/100 |

44 |

168 |

260 |

476 |

|

|

4/15/16/20/25/28/40 |

54 |

188 |

306 |

560 |

||

|

5/15/25/35/50 |

46 |

176 |

285 |

520 |

||

|

7/21/49/70 |

48 |

180 |

292 |

536 |

||

|

Reduction Ratio 減速比 |

L1: 1 Stage 單段 |

3 / 4 / 5 / 7 / 10 |

||||

|

L2: 2 Stage 雙段 |

9 / 12 / 15 / 16 / 20 / 21 / 25 / 28 / 30 / 35 / 40 / 49 / 50 / 70 |

|||||

|

L3: 3 Stage 三段 |

100 / 200 / 250 |

|||||

|

Defined Input Rotational Speed 額定輸入轉速 n1N (rpm) |

3/4/5 (L1) |

3300 |

2600 |

2300 |

2200 |

|

|

7/10 (L1) |

4000 |

2900 |

2700 |

2700 |

||

|

12 ~ 40 (L2) |

4400 |

3200 |

3000 |

3000 |

||

|

50 (L2) |

4800 |

3600 |

3300 |

3200 |

||

|

70 ~ 100 (L2) |

5500 |

4200 |

3900 |

3500 |

||

|

Backlash 精密背隙 (arcmin) |

3~10 (L1) |

≤5 |

≤5 |

≤5 |

≤5 |

|

|

12~100 (L2) |

≤8 |

≤8 |

≤8 |

≤8 |

||

|

Torsional Rigidity 扭轉剛性 (Nm/arcmin) |

3~100 (L1,L2) |

6.5 |

14 |

27 |

48 |

|

|

Max. Bending Moment 最大彎曲力矩 (N) |

3~100 (L1,L2) |

50 |

98 |

125 |

200 |

|

|

Allowable Axial Force 容許軸向力 F2aB2(N) |

3~100 L1, L2 |

2300 |

5400 |

6700 |

9000 |

|

|

Full Load Efficiency 滿載時使用效率 % |

3~10 (L1) |

≥97 |

||||

|

12~100 (L2) |

≥94 |

|||||

|

Service Life 使用壽命Lh2 (hrs) |

3~100 (L1,L2) |

20000 |

||||

|

Weight 重量 (kgs) |

3~10 (L1) |

2.3 |

4.7 |

7.4 |

22 |

|

|

12~100 (L2) |

2.8 |

5.8 |

8.9 |

29 |

||

|

Noise 噪音值 (db) |

|

65 |

65 |

64 |

64 |

|

|

Temperature 使用溫度範圍°C |

|

(-15°C ~ +90°C) |

||||

|

Protection Rank 防護等級 |

|

IP64 |

||||

|

Lubricating Oil 潤滑油 |

|

Synthetic Lubricant 合成潤滑油 ISO VG220 |

||||

|

Moment Of Inertia 轉動慣量 J1 (kg.cm) |

Stage 段數 |

Ratio 減速比 |

|

|

||

|

L1 |

3 |

0.04 |

0.78 |

2.38 |

19.8 |

|

|

4 |

0.03 |

0.6 |

2 |

17 |

||

|

5 |

0.03 |

0.59 |

2 |

17 |

||

|

7 |

0.03 |

0.73 |

2 |

16.8 |

||

|

10 |

0.04 |

0.75 |

2.3 |

19 |

||

|

L2 |

9 |

0.04 |

0.78 |

2.38 |

19.8 |

|

|

12 |

0.03 |

0.73 |

2.1 |

17 |

||

|

16 |

0.03 |

0.6 |

2.1 |

17 |

||

|

20 |

0.03 |

0.6 |

2.1 |

16.8 |

||

|

25 |

0.03 |

0.75 |

2.1 |

17 |

||

|

28 |

0.03 |

0.75 |

2.1 |

19 |

||

|

35 |

0.03 |

0.73 |

2.38 |

19 |

||

|

40 |

0.04 |

0.78 |

2.38 |

19 |

||

|

50 |

0.04 |

0.78 |

2.38 |

19 |

||

|

70 |

0.04 |

0.78 |

2.38 |

19 |

||

|

100 |

0.04 |

0.78 |

2.38 |

19.8 |

||

產品

型式

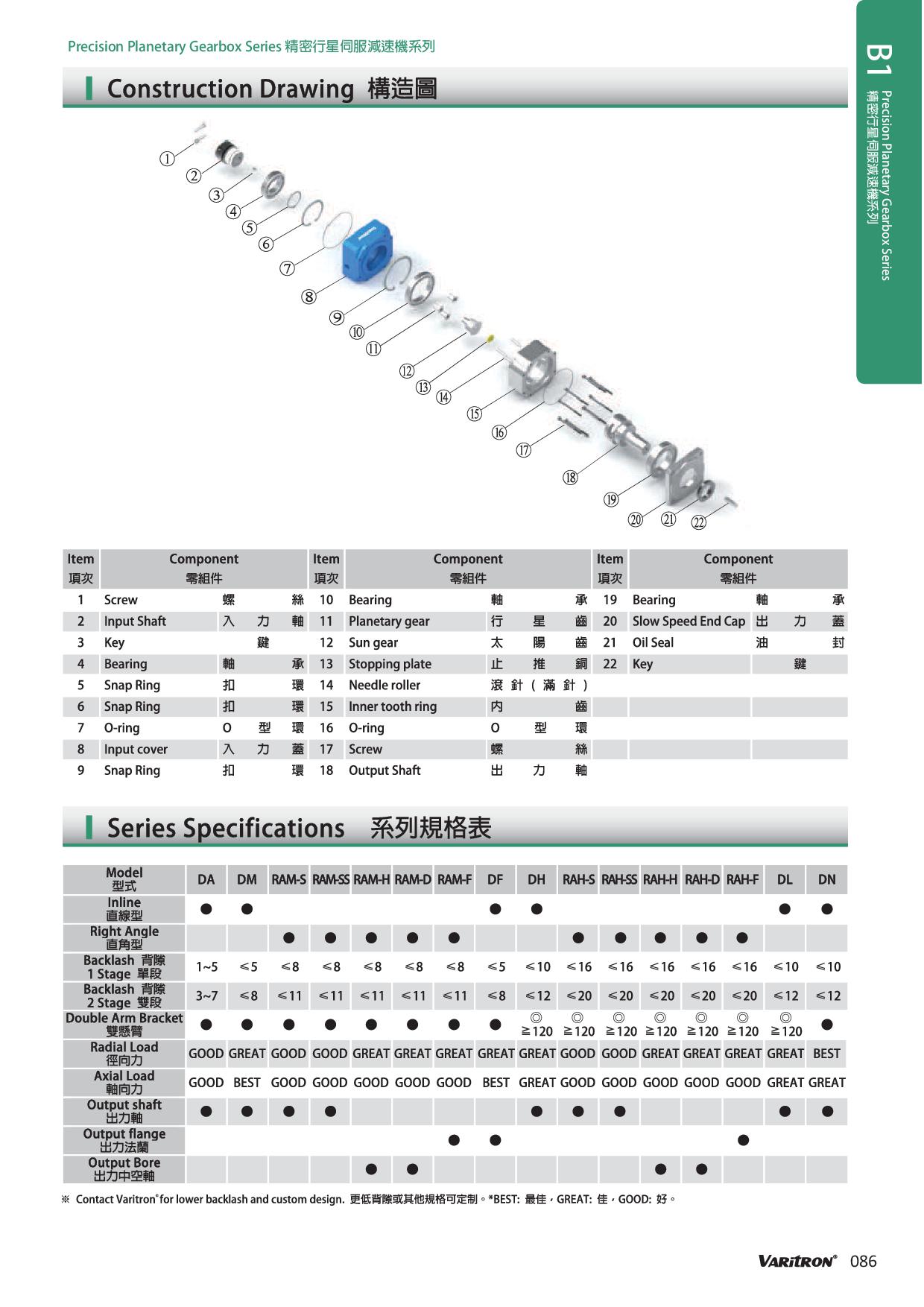

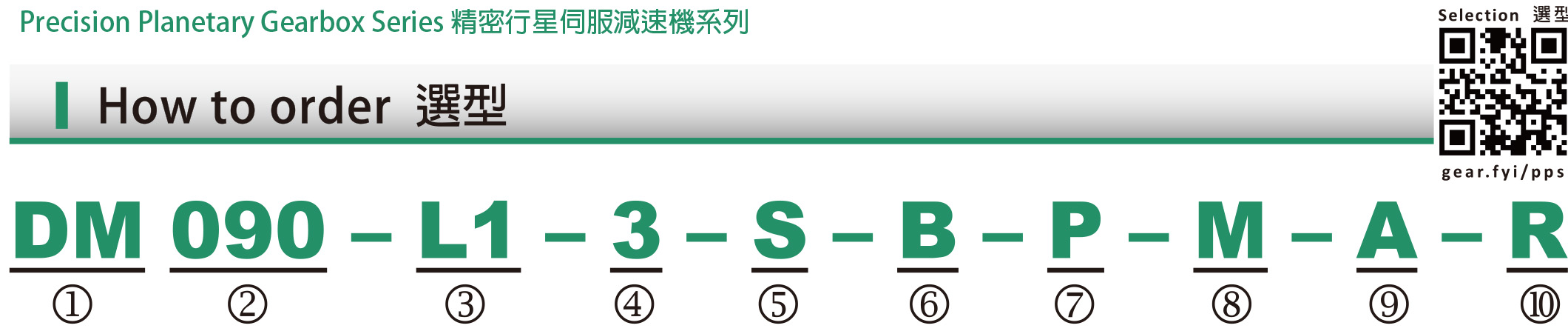

|

j |

Model型式 |

DA: Helical Gear High Precision Planetary Gearbox DM:Precision Planetary Gearbox DF:Precision Flange Type Planetary Gearbox DH:Standard Precision Planetary Gearbox DL:Standard Precision Planetary Gearbox DN:High R-A Load Standard Precision Planetary Gearbox RAM-S:Precision Shaft Output Spiral Bevel Gearbox RAM-SS:Precision Double Shaft Spiral Bevel Gearbox RAM-H:Precision Hollow Shaft Spiral Bevel Gearbox RAM-D: Precision Clamping Shaft Spiral Bevel Gearbox RAM-F: Precision Flange Spiral Bevel Gearbox RAH-S: Standard Precision Shaft Output Spiral Bevel Gearbox RAH-SS:Standard Precision Double Shaft Spiral Bevel Gearbox RAH-H:Standard Precision Hollow Shaft Spiral Bevel Gearbox RAH-D:Standard Precision Clamping Shaft Spiral Bevel Gearbox RAH-F: Standard PrecisionFlange Spiral Bevel Gearbox |

斜齒輪高精密型 精密型 法蘭式精密型 標準型 標準型 高徑軸向負荷標準型 精密單出力軸直角型 精密雙出力軸直角型 精密中空軸直角型 精密束軸直角型 精密法蘭直角型 標準單出力軸直角型 標準雙出力軸直角型 標準中空軸直角型 標準束軸直角型 標準法蘭直角型 |

|

k |

Frame Size 型號 |

042,060,070,080,090,120,150,180,220… Refer to Gearbox Quick Selection Table Page 89. 請參考快速選擇表第89頁 |

|

|

l |

Stage段數 |

L1, L2, L3 |

|

|

m |

Ratio減速比 |

L1: 3 / 4 / 5 / 7 / 10 L2: 9 / 12 / 15 / 16 / 20 / 21 / 25 / 28 / 30 / 40 / 49 / 50 / 70 L3: 36 / 45 / 60 / 75 / 80 / 150 / 200 / 300 / 400 / 500 / 700 / 1000 |

|

|

n |

Motor Shaft Diameter 馬達軸心直徑(S) |

Customized according to customer requirement. 依客戶需求訂製 |

|

|

o |

Motor Pilot Diameter 馬達引導外徑(B) |

Customized according to customer requirement. 依客戶需求訂製 |

|

|

p |

Motor Guide Depth 馬達引導深度(P) |

Customized according to customer requirement. 依客戶需求訂製 |

|

|

q |

Installing Screw P.C.D 安裝螺絲孔直徑(M) |

Customized according to customer requirement. 依客戶需求訂製 |

|

|

r |

Installing Screw Size 安裝螺絲孔內徑(A) |

Customized according to customer requirement. 依客戶需求訂製 |

|

|

s

|

Motor Shaft Length 馬達出力軸長度(R) |

Customized according to customer requirement. 依客戶需求訂製 |

|

地址:新北市五股區中興路一段171巷45號

電話:02-29889598

傳真:02-29850998

Email:[email protected]

Copyright 2014 © 中國變速工程股份有限公司 All Rights Reserved.